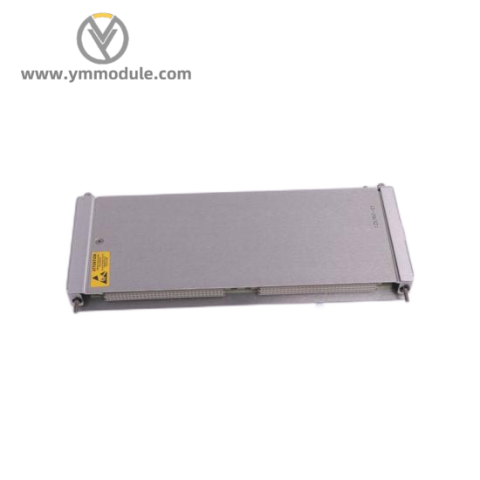

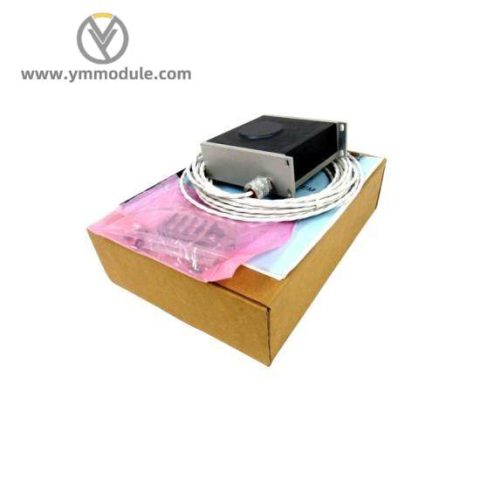

Type:Differential Expansion Monitor

Model:Bently Nevada 3300/45

Application:Industrial machinery protection

Monitoring Capacity:Up to 4 channels

Operating Temperature Range:-40°C to +85°C

Power Supply:12VDC

Communication Interface:RS485, Modbus

Dimensions:160mm x 80mm x 95mm

Weight:0.5kg

The Bently Nevada 3300/45 Differential Expansion Monitor is designed to detect minute changes in the dimensions of machinery components, which is critical for early identification of potential failures. This advanced technology ensures that maintenance actions are taken before catastrophic damage occurs, saving downtime and costly repairs.

Featuring a compact and rugged design, this monitor is suitable for a wide range of industrial applications, including petrochemical plants, power generation facilities, and manufacturing industries where equipment reliability is paramount.

With its high accuracy and robust signal processing capabilities, the Bently Nevada 3300/45 Differential Expansion Monitor provides real-time data on machinery health, allowing for predictive maintenance strategies. This proactive approach minimizes unexpected breakdowns and ensures smooth operations.

The unit supports multiple communication protocols, ensuring seamless integration with existing industrial automation systems. It is compatible with various control systems and can be easily configured for different monitoring needs through intuitive software tools.

Manufactured using premium materials and engineered to withstand harsh environmental conditions, the Bently Nevada 3300/45 Differential Expansion Monitor boasts a long service life. Its modular design allows for easy expansion and customization, meeting the evolving needs of modern industrial operations.

There are no reviews yet.